|

|

|

n this page we are going to present just a part of our manufacturing program. n this page we are going to present just a part of our manufacturing program.

The equipment we present is exclusively of our own production, being the result of our personnel's experience adopted throughout many years.

Besides the products of our own manufacture, we provide also a wide range of bakery and confectionery equipment of eminent European manufacturers. More details on supplying other equipment are available on request direct from us. |

|

|

|

| Bakery equipment - THREE-DECK SEMIAUTOMATIC BAKERY OVEN |

|

|

The oven is supplied together with the fermentation chamber, the devices for charging bake ovens and the cart for devices. Discharge of oven can be carried out by a conveyor. |

|

he oven is made in steel assembly design from high quality construction materials; it is of pleasant appearance, small dimensions and high output. he oven is made in steel assembly design from high quality construction materials; it is of pleasant appearance, small dimensions and high output.

Main advantages:

- high quality baking of all bakery and confectionery products

- simple handling, operating and maintenance

- fully independent operation of each bake oven

- very low operating costs

- four installed steamers (three for bake ovens and one for a fermentation chamber)

- possibility of its installation in existing bakeries - when old steam ovens are replaced the output is doubled.

- heating of oven either by liquid or gas fuel

| TYPE OF OVEN |

80 R |

100 R |

120 R |

| Capacity of oven |

400 kg/h |

500 kg/h |

600 kg/h |

| Total baking area |

19,2 m2 |

24,0 m2 |

28,8 m2 |

| Lenght A |

4200 mm |

5000 mm |

5800 mm |

| Lenght B |

4300 mm |

4900 mm |

4900 mm |

| Heating energy consumption |

128 kWh |

157 kWh |

186 kWh |

| El. power consumption |

4,5 kWh |

4,5 kWh |

5,5 kWh |

| Installed el. power |

5,8 kWh |

5,8 kWh |

6,8 kWh |

|

|

| Bakery equipment - DECK BAKERY OVEN |

|

t is intended for baking of all bakery and confectionery products 50-2000 grams by weight and is characterised by high quality baking, low fuel consumption, small housing space, simple operation and maintenance and by a pleasant appearance. t is intended for baking of all bakery and confectionery products 50-2000 grams by weight and is characterised by high quality baking, low fuel consumption, small housing space, simple operation and maintenance and by a pleasant appearance.

Available in two standard sizes:

Oven no. 6 – baking area - 8,9 m2

Oven no. 8 – baking area 13,2 m2

The front side of oven is made in stainless sheet metal which contributes to its

pleasant appearance throughout all its service life. Hot water boiler is installed inside the oven. The fermentation chamber is made from thermal elements or from stainless sheet metal and is located either on the left or the right side of the oven, depending upon the request by the client. It is being heated from the oven and is being moisturised by a steamer installed in the oven, i.e. specially installed heaters and electronically operated steam generators and temperature units.

| Type of oven |

External measures |

Oven measures |

External meas. of the ferment. chamber |

Fuel consumption (oil) |

El. power consumption |

Heating energy consumption |

| no. 6 |

1630x3130x2100 |

1150x1950 |

920x2840 |

4,5 kg/h |

1,5 kW |

53 kW |

| no. 8 |

2200x3130x2100 |

1700x1950 |

1450x2840 |

6,5 kg/h |

2 kW |

76 kW |

|

|

Each oven is provided with its own steam generator. Any desired temperature is very quickly reached and maintained by means of an installed thermostat.

The oven is supplied together with an electric box comprising the operating and safety elements. |

|

|

| Bakery equipment - ROTO OVEN |

|

|

|

t is intended for baking of all kinds of bakery and confectionery products and is characterised by high quality baking, low fuel consumption, small housing space, simplicity in operation and maintenance as well as a pleasant appearance. t is intended for baking of all kinds of bakery and confectionery products and is characterised by high quality baking, low fuel consumption, small housing space, simplicity in operation and maintenance as well as a pleasant appearance.

Roto-oven is designed as a convex oven with a rotary cart and vertical bake oven. It is made in stainless steel what provides for simple cleaning. Optimally sized heat exchanger is installed at the lateral or rear side and provides for maximal heat effect in regard to fuel consumption. The evaporator enables maximal steam quantity, and is being heated by hot gases from the chamber. The proper distribution of hot air provides for optimal baking of dough.

Specially designed steel gaskets at single insulated door enable thorough sealing and easy opening and closing of the door. The complete oven, control panel and insulation are made in accordance with the European standards.

|

|

|

| Type of oven |

Measuring unit |

Roto RP 90

60-90

Fire-box at the lateral side |

Roto RP 90

60-90

Fire-box at the rear side |

Roto RP 70

50-70 18 L

Fire-box at the lateral side |

Roto RP 70

50-70 18 L

Fire-box at the rear side |

Roto RP 70

50-70 15 L

Fire-box at the lateral side |

Roto RP 70

50-70 15 L

Fire-box at the rear side |

| Width |

mm |

1480 |

2180 |

1280 |

1800 |

1280 |

1800 |

| Height |

mm |

2300 |

2300 |

2300 |

2300 |

2000 |

2000 |

| Length |

mm |

2130 |

1515 |

1795 |

1275 |

1795 |

1275 |

| Weight |

kg |

1500 |

1500 |

1350 |

1350 |

1150 |

1150 |

| Heating energy consumption |

kW kcal/h |

65 |

65 |

43 |

43 |

- |

- |

| Fuel consumption |

kg/h |

7,5 |

7,5 |

5 |

5 |

- |

- |

| El. power consumption |

kW |

1 |

1 |

1 |

1 |

1 |

1 |

| Baking area |

m2 |

10 |

10 |

6 |

6 |

5 |

5 |

|

|

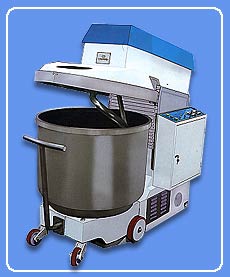

| Bakery equipment - INTENSIVE KNEADER |

|

he kneader is made in high quality materials; casing in solid cast iron, vessel and spiral in stainless steel, protective covers in aluminium cast. he kneader is made in high quality materials; casing in solid cast iron, vessel and spiral in stainless steel, protective covers in aluminium cast.

It is designed for fully automatic operation by means of a programmer, what enables the implementation of two mixing speeds; the kneading itself does not last more than 5 minutes. Operation is simple, the machine is fully protected and the handling is safe and reliable.

Lifting of the operating head and fixation of the vessel to the machine is carried out automatically. The electric control unit represents an achievement of a long term research and development by our specialist team and presents the best solution for fully automatic operation of the machine. The construction of the kneader allows application of 280-l volume and 400 l volume vessels, provided that some minor modifications are to be made while the same casing and the same programmer are employed.

| List of equipment |

Tip IM-200 |

Tip IM-280 |

- |

| Driving motor |

1st speed |

4,6 |

6 |

kW |

| 2nd speed |

6 |

8,5 |

kW |

| Driving friction-wheel motor |

0,55 |

0,55 |

kW |

| Lifting device motor |

0,55 |

0,55 |

kW |

| Mixer revolution number |

1st speed |

70 ili 90 |

70 ili 90 |

1/min |

| 2nd speed |

140 ili 180 |

140 ili 180 |

1/min |

| Vessel |

Volume |

280 |

400 |

mm |

| Diameter A |

793 |

952 |

mm |

| Total machine length B |

1560 |

1690 |

mm |

| Total machine width |

850 |

1020 |

mm |

| Total machine weight |

1000 |

1050 |

cca kg |

|

|

|

Its pleasant appearance, high quality design, small dimensions, extraordinary

kneading, simple and safe operation make it exceptional in the market.

On request, it is made with higher revolution speed of a spiral.

|

|

|

|

|

|

| Intensive Kneader |

Total weight (kg) |

Maximal power (KW) |

Capacity (kg) |

Size (cm) |

| IM 30 |

145 |

1,1 |

11-18 |

47x75x90 |

| IM 40 |

195 |

1,6 |

23-25 |

53x82x104 |

| IM 60 |

365 |

4,6 |

30-36 |

66x106x114 |

| IM 80 |

390 |

4,6 |

47-50 |

71x112x116 |

| IM 100 |

420 |

5,0 |

62-65 |

78x120x120 |

| IM 130 |

595 |

7,0 |

75-80 |

85x140x132 |

| IM 160 |

705 |

7,5 |

100 |

89x149x139 |

| IM 200 |

720 |

7,5 |

125 |

95x154x139 |

| IM 250 |

820 |

9,0 |

150 |

103x161x139 |

| IM 300 |

860 |

11,9 |

180 |

109x167x139 |

|

|

|

This machine is suitable for processing both bread and pastry dough, and guarantees delicate treatment of dough and precisely measured pieces Division of the dough vary from 30 to 1300 g depending on the size of the piston.

Machine has fixed speed of 23, 28, 34, pcs/min, but it can be equipped with the speed variator on request.

Divider is also equipped with supplement for rounding the dough pieces, so extra machine for rounding is needless.

Machine has the stainless steel hopper with capacity of 50 kg. (possible 150 kg hopper) Machine dimensions are 1750x680x1410(h), and weight is 450 kg. Installed power is 3 kW.

|

|

| Type |

Frequency |

Voltage |

Total machine weight |

Hopper height (60kg) |

Hopper height (120 kg) |

Total machine width |

| VD 30 |

50Hz |

380 V |

450 kg |

1410 mm |

1560 mm |

680 mm |

| Total machine lenght |

Maximal power |

Optimal fixed speed pcs/min |

Size of the piston 90 mm |

Size of the piston 110 mm |

Size of the piston 130 mm |

| 1750 mm |

3 Kw |

20-40 |

30-300 gr. |

100-1000 gr. |

150-1200 gr. |

|

|

|